濟南歌德瑞斯機械設備有限公司,是窗門制造機器行業的一家集研發、設計、生產、銷售、服務為一體的綜合性公司。

嚴格按照行業標準和出口標準組織生產。機器的優良品質和優異性能已被客戶廣泛認可。同時,公司繼續加大對產品研發的投入,以增強產品的核心競爭優勢。

嚴格按照行業標準和出口標準組織生產。機器的優良品質和優異性能已被客戶廣泛認可。同時,公司繼續加大對產品研發的投入,以增強產品的核心競爭優勢。

滾壓復合機的生產有什么特征?

發布時間:2024-12-10 來源:http://www.asilen.cn/

滾壓復合機是一種用于材料加工的設備,主要用于將不同材料通過滾壓的方式緊密結合在一起。以下是滾壓復合機的一些關鍵特點和應用:

Rolling composite machine is a device used for material processing, mainly used to tightly bond different materials together by rolling. The following are some key features and applications of the rolling composite machine:

工作原理:滾壓復合機通過滾壓裝置將需要復合的材料擠壓到一起。它利用金屬在常溫狀態下的冷塑性特點,通過滾壓刀具對工件表面施加一定壓力,使工件表層金屬產生塑性流動,從而降低表面粗糙度,改善工件表面的耐磨性、耐蝕性和配合性。

Working principle: The rolling composite machine squeezes the materials that need to be composite together through a rolling device. It utilizes the cold plasticity characteristics of metals at room temperature by applying a certain pressure to the surface of the workpiece through rolling tools, causing plastic flow of the metal on the surface of the workpiece, thereby reducing surface roughness, improving the wear resistance, corrosion resistance, and fit of the workpiece surface.

應用領域:滾壓復合機廣泛應用于家紡、服裝、家具、汽車內飾及相關產業中,主要用于布料、皮革、膜、紙、海綿等材料的二層或多層貼合生產工藝。具體包括有膠復合和無膠復合,如水膠、PU油膠、熱熔膠等。

Application areas: Roll laminating machines are widely used in home textiles, clothing, furniture, automotive interiors, and related industries, mainly for the production process of two-layer or multi-layer bonding of materials such as fabrics, leather, films, paper, sponges, etc. Specifically, it includes adhesive composite and non adhesive composite, such as water-based adhesive, PU oil adhesive, hot melt adhesive, etc.

技術特點:

Technical features:

采用三組硬質滾壓輪,將開完齒并穿好隔熱條或塑料異型材的鋁型材壓合牢固,實現鋁型材和隔熱條的緊密結合。

Using three sets of hard rolling wheels, the aluminum profiles with opened teeth and insulation strips or plastic profiles are firmly pressed together to achieve a tight bond between the aluminum profiles and insulation strips.

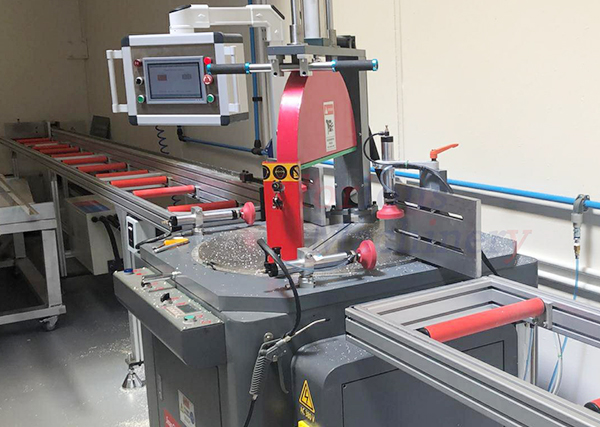

一些滾壓復合機采用“兩軸數控系統”,滾壓刀盤升降軸實現數控調整,上尼龍輪實現數控調整,提高自動化程度。

Some rolling compound machines adopt a "two axis CNC system", where the lifting shaft of the rolling cutter head is adjusted by CNC, and the upper nylon wheel is adjusted by CNC to improve the degree of automation.

配備LCD液晶觸摸操作顯示屏,可實現加工數據的存儲、調用,實現更換各種型材的完全自動化。

Equipped with an LCD touch operation display screen, it can store and call processing data, and achieve complete automation in replacing various profiles.

全時六驅,六套動力系統,傳動軸傳動,變頻器無級調速。

Full time six wheel drive, six power systems, transmission shaft drive, variable frequency drive with stepless speed regulation.

性能優勢:

Performance advantages:

滾壓復合機能夠提高材料的表面抗腐蝕能力,并延緩疲勞裂紋的產生或擴大,提高油缸桿疲勞強度。

Rolling composite machine can improve the surface corrosion resistance of materials, delay the generation or expansion of fatigue cracks, and enhance the fatigue strength of oil cylinder rods.

滾壓后,表面粗糙度值減小,提高配合性質,降低光桿活塞運動時對密封圈或密封件的摩擦損傷,提高部件的整體使用壽命。

After rolling, the surface roughness value decreases, improving the fitting properties, reducing the friction damage to the sealing ring or seal during the movement of the rod piston, and improving the overall service life of the component.

滾壓工藝較磨削工藝效率提高15倍左右,油缸使用壽命提高2~3倍。

The rolling process is about 15 times more efficient than the grinding process, and the service life of the oil cylinder is increased by 2-3 times.

傳感器應用:滾壓復合機可能配備多種傳感器,如位移傳感器、速度傳感器、加速度傳感器等,用于測量和監測機器的參數,為機器的精確控制和優化提供數據支持。

Sensor application: The rolling compound machine may be equipped with various sensors, such as displacement sensors, velocity sensors, acceleration sensors, etc., to measure and monitor the parameters of the machine, providing data support for precise control and optimization of the machine.

滾壓成型工藝:滾壓成型工藝具有生產效率高、節約材料、增加產品強度等優點,適用于大批量生產,特別是在汽車、自行車等工業部門中應用廣泛。

Rolling forming process: Rolling forming process has the advantages of high production efficiency, material saving, and increased product strength, and is suitable for large-scale production, especially widely used in industrial sectors such as automobiles and bicycles.

設備性能:主要元器件采用進口配件,性能可靠,整機噴塑,美觀耐用。

Equipment performance: The main components are made of imported accessories, which are reliable in performance. The whole machine is spray painted, beautiful and durable.

綜上所述,滾壓復合機是一種高效的材料加工設備,通過精確控制和優化,能夠提高材料的性能和使用壽命,廣泛應用于多個工業領域。

In summary, the rolling composite machine is an efficient material processing equipment that can improve the performance and service life of materials through precise control and optimization, and is widely used in multiple industrial fields.

本文由滾壓復合機為您提供,我們的網站是:http://www.asilen.cn我們將以全心全意的熱情為您提供服務,歡迎您的訪問!

This article is provided by the rolling laminating machine. Our website is: http://www.asilen.cn We will provide you with wholehearted enthusiasm and welcome your visit!

熱門產品 / HOT PRODUCT